Neocraft modular lamp

European Product Design Award 2023 prize

The Neocraft modular lamp is a customisable system of DIY lamps designed to be produced with desktop 3D printers and to be assembled with basic hardware store parts, optimising flexibility and minimising waste.

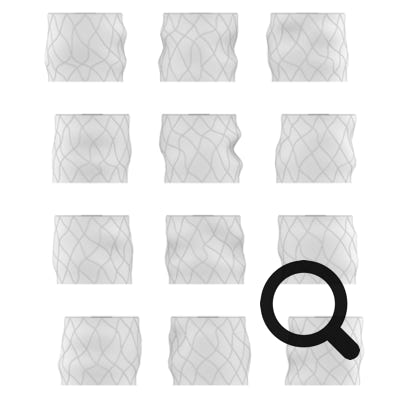

3D printed parts are generated through a script which creates a new shape every time, making every iteration unique. In spite of their uniqueness, all parts can be combined and recombined with all other parts in a flexible manner.

No glue and no 3D print building support structures are required at any point. After the use cycle all parts can be either reused or recycled.

This project was born as a case study for my PhD research at The Oslo School for Architecture and Design AHO.

The neocraft modular lamp won in two categories at the European Product Design Awards 2023: Home - home lighting and Eco design/Sustainable - home products.

Read the project’s full description here.

The best part of the neocraft modular lamp is that it is designed for you to produce it by yourself with a desktop 3D printer!

Just download the following STL or G-code files (for Ultimaker 2) and print them. Or even better, generate new and unique shapes with the Grasshopper scripts bellow.

Grasshopper script bottom part

Grasshopper script middle part

Grasshopper script top part

Grasshopper script lamp in single module

G-code bottom part 1 G-code bottom part 2 G-code bottom part 3 G-code bottom part 4 G-code bottom part 5 G-code bottom part 6 G-code bottom part 7 G-code bottom part 8 G-code bottom part 9 G-code bottom part 10

STL bottom part 1 STL bottom part 2 STL bottom part 3 STL bottom part 4 STL bottom part 5 STL bottom part 6 STL bottom part 7 STL bottom part 8 STL bottom part 9 STL bottom part 10

G-code middle part 1 G-code middle part 2 G-code middle part 3 G-code middle part 4 G-code middle part 5 G-code middle part 6 G-code middle part 7 G-code middle part 8 G-code middle part 9 G-code middle part 10

STL middle part 1 STL middle part 2 STL middle part 3 STL middle part 4 STL middle part 5 STL middle part 6 STL middle part 7 STL middle part 8 STL middle part 9 STL middle part 10

G-code top part 1 G-code top part 2 G-code top part 3 G-code top part 4 G-code top part 5 G-code top part 6 G-code top part 7 G-code top part 8 G-code top part 9 G-code top part 10

STL top part 1 STL top part 2 STL top part 3 STL top part 4 STL top part 5 STL top part 6 STL top part 7 STL top part 8 STL top part 9 STL top part 10

G-code single-module 1 G-code single-module 2 G-code single-module 3 G-code single-module 4 G-code single-module 5 G-code single-module 6 G-code single-module 7 G-code single-module 8 G-code single-module 9 G-code single-module 10

STL single-module 1 STL single-module 2 STL single-module 3 STL single-module 4 STL single-module 5 STL single-module 6 STL single-module 7 STL single-module 8 STL single-module 9 STL single-module 10

All models shown in the pictures were produced with Ultimaker 2+ printers and PLA material.

Each module is 160 mm. tall.

Use the „fuzzy skin“ option in Cura (slicer) in order to get the textured surface shown in the pictures.

If you use the Grasshopper scripts take into account that due to the many randomised parameters sometimes the resulting geometries can be invalid. In case that happens generate a new iteration by changing the randomising values.

The legs are made with 16 mm. diameter circular wooden rods. The lamps in the pictures use rods from 130 to 150 mm. in length. Just fit them in, no glue needed.

The lightbulb sockets are standard E14 holders with a screw shade holder (see pictures above). The lightbulbs must be E14 as well. We recommend using only LED lightbulbs due to heat.

The screws needed for multiple storey lamp assembly are wooden screws, 3.5 mm. in diameter, 20 mm. long.

In case you build a multi-storey lamp assemble it from the bottom to the top (the screws come from the top to the bottom). Don’t forget to install the lightbulb sockets and lightbulbs before placing the next level.

There are many possible solutions to wiring for the lamp. Depending on the number of storeys you are building different strategies can work in a better way. The design includes holes to hold and guide the cables along the structure. If you follow the spiral pattern with them the shadow they cast will blend with the structure in a better manner (see picture bellow). Depending on the number of storeys you may need to do the wiring as you build up since accessing the interior of the modules becomes increasingly difficult, or impossible, after three storeys.

Use this wiring technique to keep cables away from the lightbulbs and integrate their shadow into the lamp’s pattern.

Any hazardous result or injury provoked by the use of these files is only and entirely the responsibility of the user. We have designed and tested this model to be safe but wrong wiring, wrong assembly, and/or wrong use of electric devices in general can always be dangerous.

© Ricardo Simian 2019 - 2026 all rights reserved

Google Analytics is a web analysis service provided by Google. Google utilizes the data collected to track and examine the use of this site, to prepare reports on its activities and share them with other Google services.

Google may use the data collected to contextualize and personalize the ads of its own advertising network.

Personal data collected: Cookie and Usage Data. Place of processing: USA. Find Google's privacy policy here.